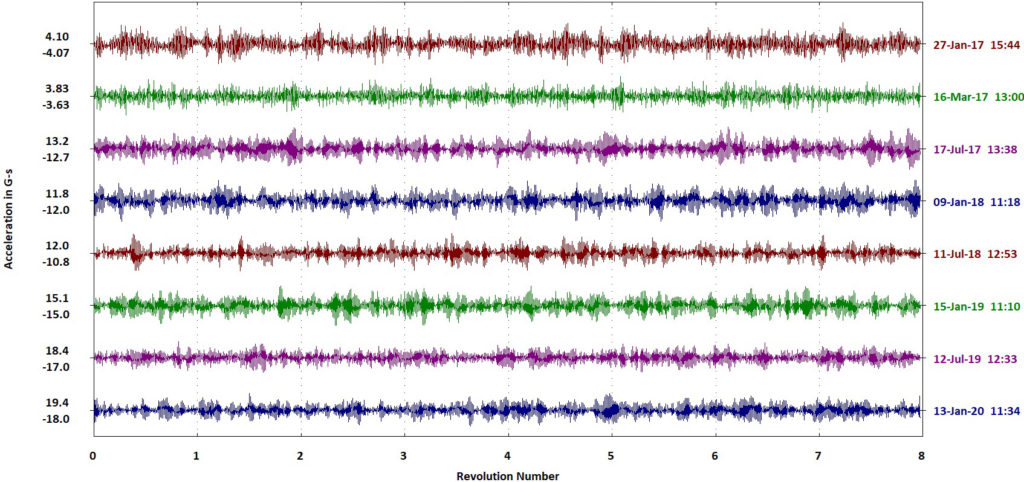

Vibration analysis is a process for measuring the vibration levels and frequencies of machinery and then using that information to identify, predict, and prevent failures in rotating machinery.

Learn More

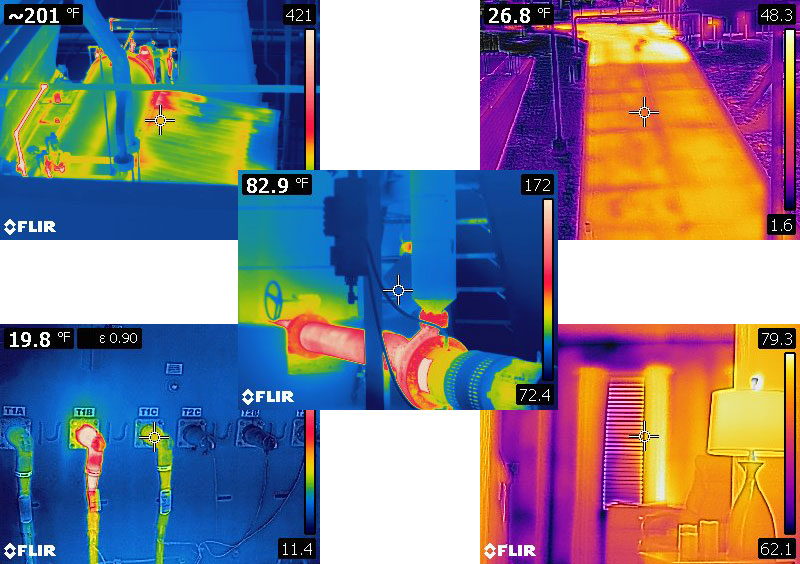

Identify failing components using heat signatures from electrical and mechanical equipment for route based or new equipment commissioning.

Learn More

Using state of the art test equipment we can identify leaks in steam, vacuum, compressed air and gas systems.

Learn More

Oil is the life blood of a machine. By testing for wear, contaminants and chemistry we can identify changes occurring with machinery.

Learn More

Adding or removing weight to fans, grinders, hammer mills, cooling towers, compressor wheels to reduce machine vibration, heat in bearings and energy consumption.

Learn More

Video motion amplification is a proprietary video processing algorithm that detects subtle motion and amplifies that motion to a level that is visible with the naked eye allowing the user to understand how machine or system components are moving in relationship to each other or a stationary object/reference.

Learn More

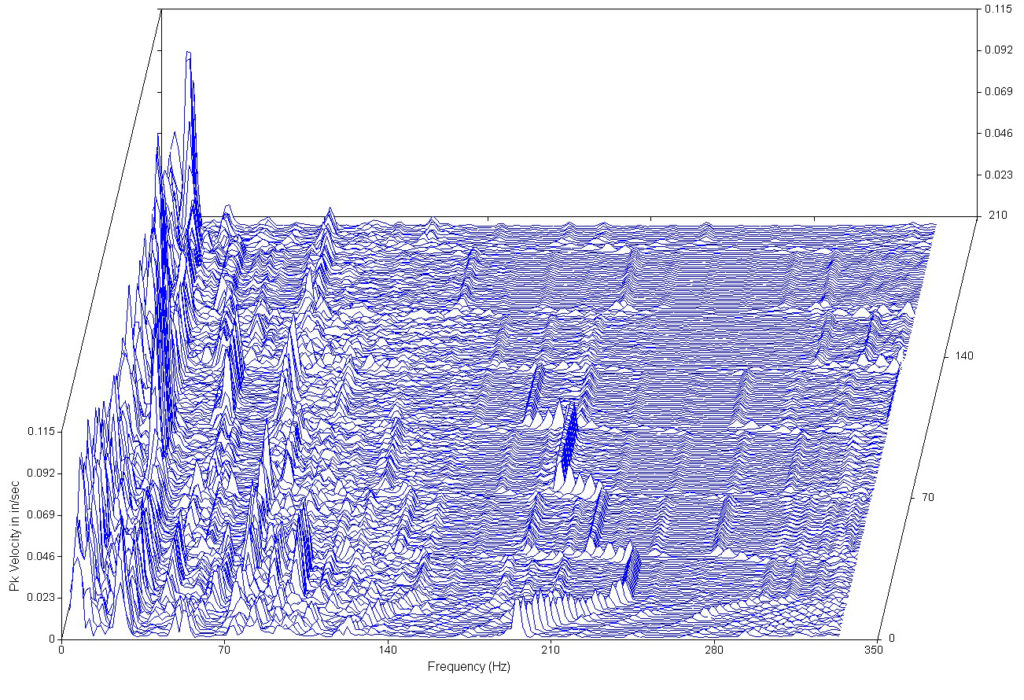

Phase Analysis, Natural Frequency Testing, Startup / Coast down data along with process data are used to identify advanced faults with new or used machinery.

Learn More

Visual inspection is performed during normal route collection or site assessment of your facility. Findings come from a wide array of rotating and stationary components.

Learn More